Laser Cutting Vs. Laser Engraving - What's The Difference?

So, you've got a project in mind, maybe a piece of intricate metalwork for a construction gig or custom signage for your business, and you're thinking, "I need lasers for this!"

Good choice! But wait, laser cutting or laser engraving?

Confused? You're not alone. Laser technology has come a long way, and although these methods might sound similar, they serve different purposes. Buckle up as we break down the essential differences between

laser cutting

and laser engraving, and help you decide which one suits your needs.

Understanding the Basics: What Is Laser Cutting & Laser Engraving?

Laser Cutting: Like a Hot Knife Through Butter

Imagine an ultra-powerful, focused beam of light, zipping through materials with finesse and speed. That’s laser cutting for you. This technology uses a high-powered laser to slice through materials like metal, wood or plastics, leaving behind a smooth, clean cut. It’s precise, it’s quick and it's like a superhero power for materials.

Laser Engraving: The Master of Etch

On the other side of the laser spectrum is laser engraving. Think of it as the tattoo artist for inanimate objects. A laser beam removes the surface layer of the material to create a permanent design. This process is excellent for detailed artwork, labelling parts or creating that intricate logo on your favourite mug.

Key Differences: From Material Compatibility To Depth Of Cut

What Can They Cut? Or Not?

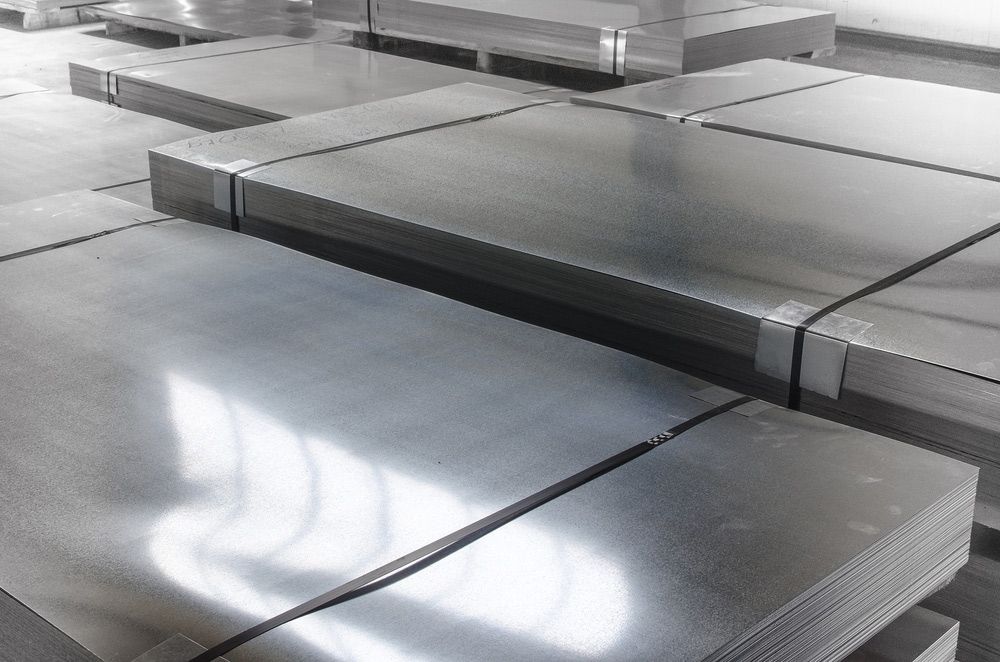

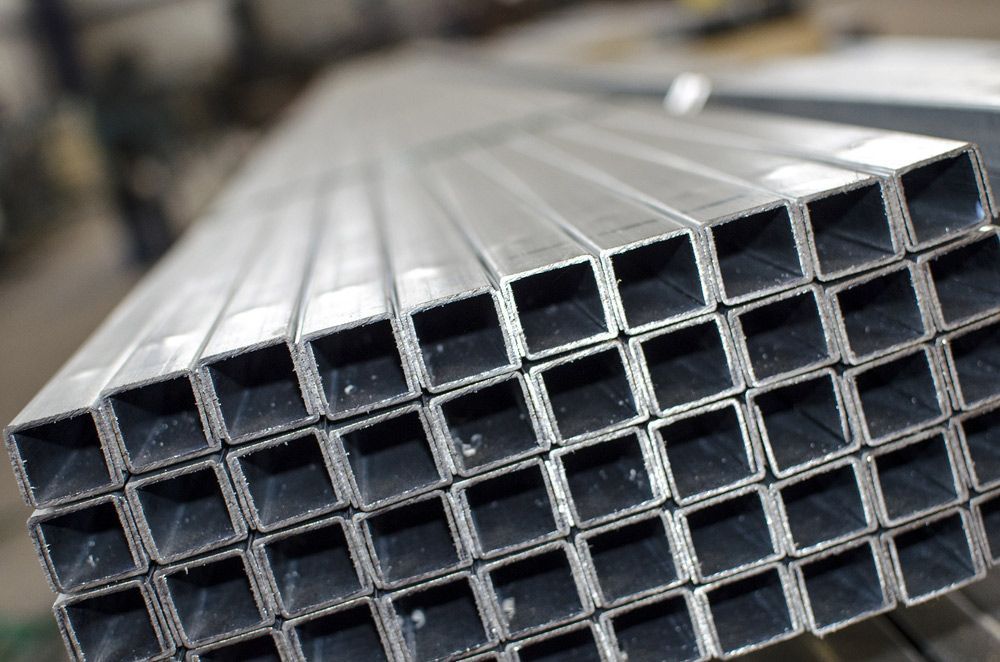

Laser cutting is the go-to option for heavy-duty materials like metals and thick plastics. On the flip side, laser engraving is better suited for softer materials like wood, leather and some plastics, although it can etch metals as well.

How Deep Do They Go?

In laser cutting, the laser penetrates completely through the material, creating a cut-out. In engraving, the laser only removes the top layer, providing textural and visual contrast without cutting through the object.

Speed & Power

Laser cutting typically requires more power and time as it has to cut through materials, whereas engraving is faster but uses less energy.

Practical Applications: When To Use Laser Cutting Vs. Laser Engraving

Cutting: The Constructor’s Delight

In construction and manufacturing, laser cutting reigns supreme for its ability to produce uniform, repetitive cuts. Imagine cutting out the same, complicated design in sheet metal over and over again with traditional methods. Nightmare, right?

Engraving: The Artisan's Muse

Where laser cutting is more utilitarian, engraving is the artistic sibling. It’s perfect for creating detailed designs, personalising gifts or even engraving barcodes and serial numbers for product tracking.

Cost & Efficiency: A Comparative Analysis

Laser cutting generally costs more due to the higher power consumption and longer time required to cut through materials. However, it becomes cost-effective for bulk orders. Laser engraving, while cheaper for smaller jobs, can get costly if you’re looking for extreme detail over a larger surface area.

Parting Beams: The Takeaway On Lasers

Both laser cutting and laser engraving offer a world of possibilities, but understanding their unique features, advantages and limitations will help you make an informed decision.

Are you based in Dubbo and have a fabrication project screaming for some laser action? Look no further than Agriweld Engineering, the go-to for professional laser cutting in Dubbo. Our team of experts will guide you through the entire process, ensuring the laser technology you choose aligns perfectly with your project's needs. Contact us today on (02) 6882 2934 for a consultation and make laser magic happen for you!

Agriweld Engineering is a local family owned company that has being servicing the central west for over 35 years

QUICK LINKS

BUSINESS HOURS

Mon - Thurs: 7am-4pm

Friday: 7am -1pm

Sat - Sun: Closed

© Copyright 2021 | All Rights Reserved | Agriweld Engineering