Exploring The Benefits Of Customised Welding Solutions For Agricultural Machinery

In the agricultural industry, there is a growing need for sturdy machinery capable of enduring tough working conditions.

Customised welding solutions play an important role in meeting these needs. In this blog post, we’ll delve into how tailored welding services can significantly improve agricultural machinery. Understanding these aspects will help you appreciate the vital role of advanced welding in modern agriculture.

Precision And Durability

Precision in welding is critical when it comes to agricultural machinery. The exact alignment and secure joining of parts ensure that the equipment can endure the rigours of farming tasks. Customised welding provides:

- Precision that standard assembly lines cannot match, addressing the unique structural requirements of each piece of machinery.

- Enhanced strength in joints, which reduces wear and tear, prolonging the machinery's operational life.

Durability is equally important. The harsh environmental conditions often faced in agricultural settings demand materials and construction that resist corrosion and breakage. Customised welding:

- Uses premium materials designed to withstand adverse weather and chemical exposures.

- Incorporates techniques like MIG and TIG welding, which are renowned for their deep penetration and strong bonds, ensuring that machinery components hold up under tough conditions.

Enhanced Efficiency And Longevity

Efficient machinery is essential for productive farming. Customised welding can improve the efficiency of agricultural equipment by:

- Reducing the weight of the machinery while maintaining strength through the use of advanced metals and alloys.

- Optimising the design to enhance performance, such as improving hydraulic systems through better joint configurations.

The longevity of machinery directly impacts the bottom line for farmers. It means:

- Fewer breakdowns and less downtime, which are critical during peak agricultural seasons.

- High-quality welds, which extend the time between necessary repairs and reduce maintenance costs over the lifespan of the equipment.

Custom Solutions For Agricultural Performance

Every farming operation has unique needs based on the crops, climate and terrain. Tailored welding caters precisely to these needs by:

- Adapting equipment for specific tasks, which can vary widely from general ploughing to specialised crop harvesting.

- Enhancing the machinery's versatility, allowing for quick changes between tasks and thus increasing overall farm productivity.

This level of customisation helps in achieving optimal agricultural performance, as machinery is specifically tailored to the farm’s operational requirements.

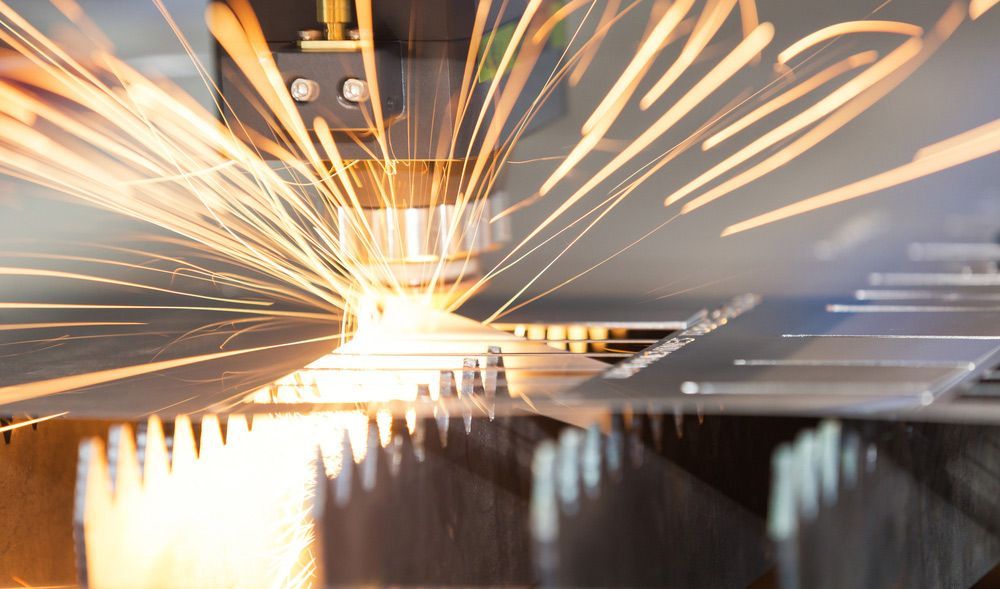

Advanced Techniques For Stronger Joints

The integrity of welded joints is crucial for the safe operation of heavy agricultural equipment. Advanced welding techniques include:

- Resistance welding: It employs an electric current to heat metal for quick and efficient welds. It is ideal for welding sheet metal.

- Laser welding: It offers unmatched accuracy and control. This technique is suitable for detailed work where minimal heat exposure is necessary to prevent material warping.

These sophisticated techniques result in stronger, more reliable joints that are crucial for the heavy loads and intense work cycles typical of agricultural machinery.

Contact Us For Your Welding Needs!

A common concern about customised welding in agricultural applications is the misconception that it is only suitable for large-scale or highly specialised machinery. However, welding is incredibly versatile and can be adapted to benefit a wide range of agricultural equipment, from small machinery to large tractors.

At Agriweld Engineering, we offer tailored welding services designed to meet the specific requirements of your farming operations. We are here to assist with your welding needs, ensuring that your machinery performs at its best. Reach out today!

Agriweld Engineering is a local family owned company that has being servicing the central west for over 35 years

QUICK LINKS

BUSINESS HOURS

Mon - Thurs: 7am-4pm

Friday: 7am -1pm

Sat - Sun: Closed

© Copyright 2021 | All Rights Reserved | Agriweld Engineering