What Are The Different Types Of Fabrication?

From the towering skyscrapers that grace our city skylines to the intricate components of our everyday gadgets,

fabrication is the driving force behind their creation. It is a process that breathes life into raw materials, transforming them into the objects we rely on and admire. If you have a project that requires fabrication, read on to uncover the different types and techniques that make it all possible. By understanding the types of fabrication and their applications, you can select the most suitable techniques and materials for your project, ensuring optimal results.

A Closer Look At Fabrication Techniques

Fabrication involves cutting, shaping, assembling and joining different materials to achieve the desired form and functionality. The processes vary significantly based on the materials involved, as each of them requires specific techniques and tools to achieve the desired outcome.

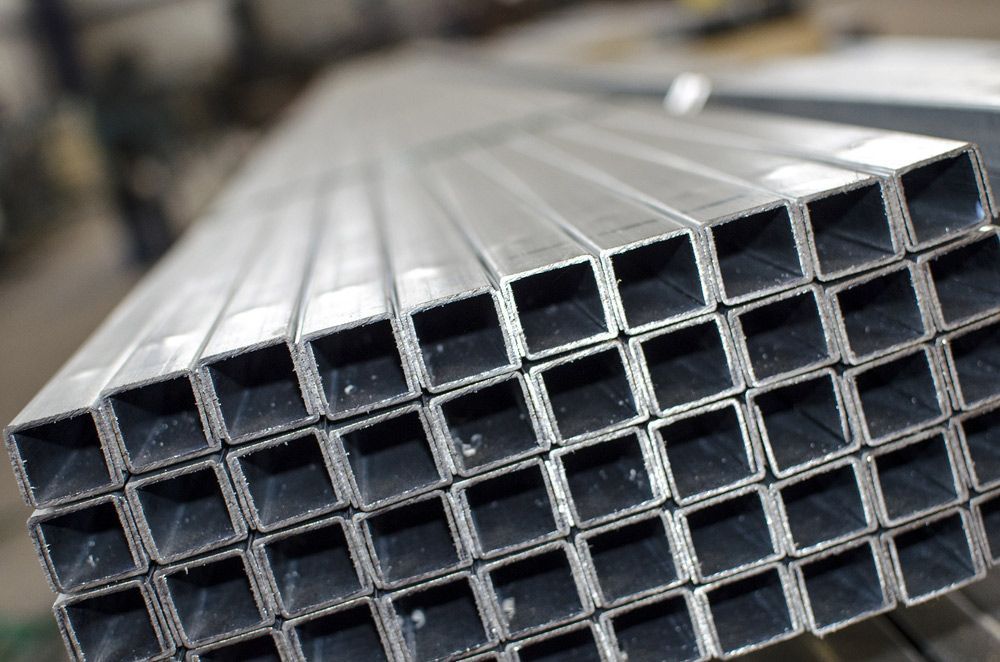

1. Metal Fabrication

Metal fabrication is one of the most common types and is widely used in industries such as automotive, aerospace and construction. It involves working with various metals, including steel, aluminium and copper, to create structures and components. Metal fabrication techniques include:

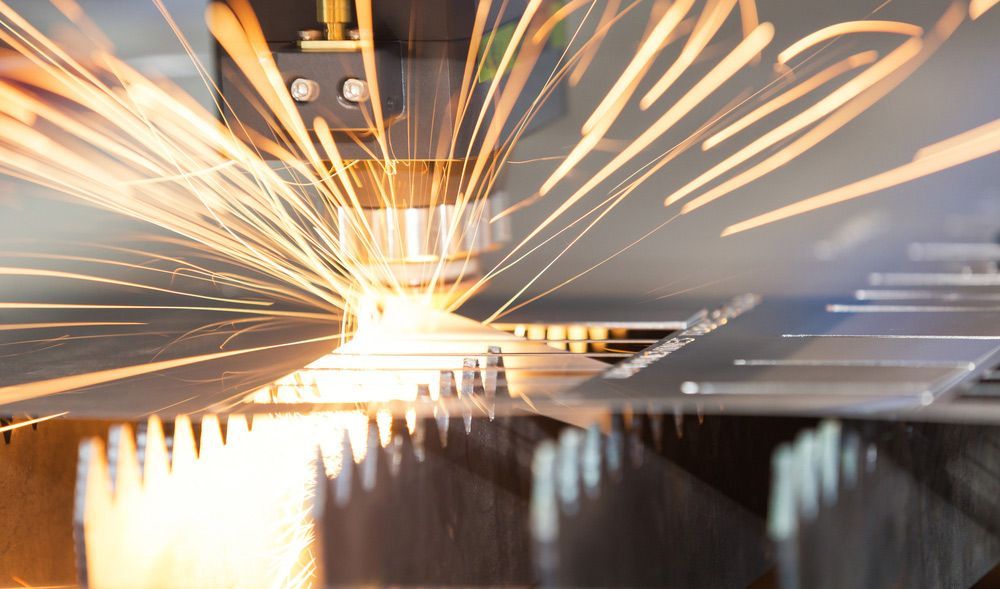

- Cutting: Metal cutting utilises different methods such as shearing, sawing or laser cutting. These techniques enable precise and accurate shaping of the metal.

- Bending: Bending involves applying force to deform it into the desired shape either manually or with the help of specialised tools like press brakes.

- Welding: Welding joins metal pieces together by melting and fusing them. Common welding methods include MIG (Metal Inert Gas), TIG (Tungsten Inert Gas) and arc welding.

- Machining: Machining refers to the use of various tools, such as lathes, milling machines and drills, to remove material from a workpiece and shape it to the desired specifications.

2. Plastic Fabrication

Plastic fabrication is another widely used process, particularly in industries like packaging, electronics and consumer goods. It involves working with different types of plastics, including acrylic, polyethene and PVC, to create a variety of products. Plastic fabrication techniques include:

- Moulding: Plastic moulding techniques, such as injection moulding and blow moulding, use heat and pressure to shape molten plastic into specific forms. This process is highly efficient for producing large quantities of identical parts.

- Thermoforming: Thermoforming involves heating a plastic sheet and then shaping it using a mould. This technique is often used for creating packaging materials, trays and various consumer products.

- CNC Machining: Computer Numerical Control (CNC) machining is used to carve, mill and shape plastic materials with high precision. CNC machines follow pre-programmed instructions to create complex designs.

3. Wood Fabrication

Wood fabrication techniques have been used for centuries, and they continue to play an important role in industries such as furniture making, construction and cabinetry. Wood fabrication involves shaping and assembling wood to create functional and aesthetic structures. Common wood fabrication techniques include:

- Cutting and Shaping: Cutting and shaping wood can be done using various tools such as saws, routers and planers. These tools help create precise cuts and smooth edges.

- Joinery: Joinery techniques like dovetail joints and biscuit joints are used to connect different wood pieces securely. These methods ensure the structural integrity and longevity of wooden structures.

- Finishing:

Finishing techniques, such as sanding, staining and varnishing, enhance the appearance and protect the wood from damage caused by moisture, UV rays and wear.

4. Composite Fabrication

Composite fabrication involves working with materials composed of two or more different components, typically combining a reinforcing material with a resin matrix. Composites offer excellent strength-to-weight ratios and are used in industries like aerospace, automotive and sports equipment. Common composite fabrication techniques include:

- Layup: Layup involves arranging layers of reinforcing material, such as fibreglass or carbon fibre, in a mould and applying resin to create a composite structure.

- Compression Moulding: Compression moulding uses heat and pressure to shape and cure composite materials. It is suitable for producing complex shapes with high strength.

- Filament Winding: Filament winding involves winding fibres around a rotating mandrel to create composite structures like pipes or pressure vessels.

Specialised Metal And Steel Fabrication Services In Dubbo

If you need professional fabrication services in Dubbo, turn to Agriweld Engineering. Our experienced team will assist you at every stage of the fabrication process, from the initial design phase to the final product. Whether you require custom metal components, precise plate cutting or just professional advice, we are here to help.

Agriweld Engineering is a local family owned company that has being servicing the central west for over 35 years

QUICK LINKS

BUSINESS HOURS

Mon - Thurs: 7am-4pm

Friday: 7am -1pm

Sat - Sun: Closed

© Copyright 2021 | All Rights Reserved | Agriweld Engineering